Laboratory Gas Pipeline Stainless Steel Pressure Gauge

- BRT

- China

- 7 Working Days

- 1000pcs/momth

ASTM D1267 Gauge Vapor Pressure of Liquefied Petroleum (LP) Gases Test Bomb

Gasoline and Diesel Typical Vapor Pressure Apparatus with Valves

Upper and Lower Chambers

LPG Vapor Pressure Apparatus/Test Bomb

Model: BZYT

Laboratory gas pipeline,Stainless steel pressure gauge,Sampling cylinder accessories

LPG Vapor Pressure Test Bomb is conforming to ASTM D1267 <Standard Test Method for Gauge Vapor Pressure of Liquefied Petroleum (LP) Gases (LP-Gas Method)> , ASTM D323, ISO 3007 and GB/T 6602.

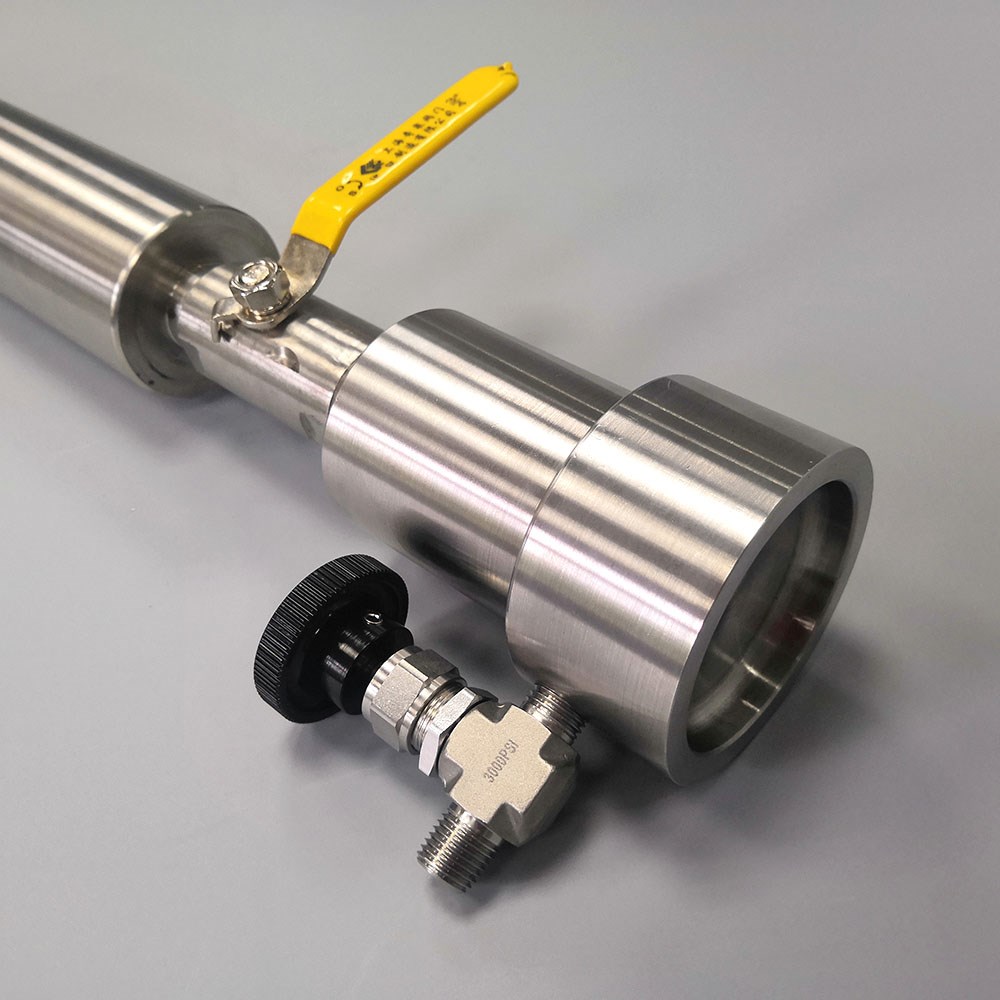

Applicable for the determination of gauge vapor pressure of LPG at temperatures of 37.8ºC up to and including a test temperature of 70ºC. Composed of upper and lower chambers that can be connected to each other, Inlet Valve, Bleeder Valve, Staright-Through Valve and a pressure gauge(purchase yourself). Two chambers conform to the following requirements. To maintain the correct volume ratio between the upper and lower chambers, the units are not interchanged without recalibrating to ascertain that the volume ratio is within satisfactory limits.

Upper Chambers: This chamber shown in photo, is a cylindrical vessel with the inner surfaces of the ends slightly sloped to provide complete drainage from either end when held in a vertical position. On one end of the chamber, a suitable bleeder valve coupling provided to receive the bleeder valve assembly and the pressure gauge. In the other end of the chamber an opening provided for coupling with the lower chamber.

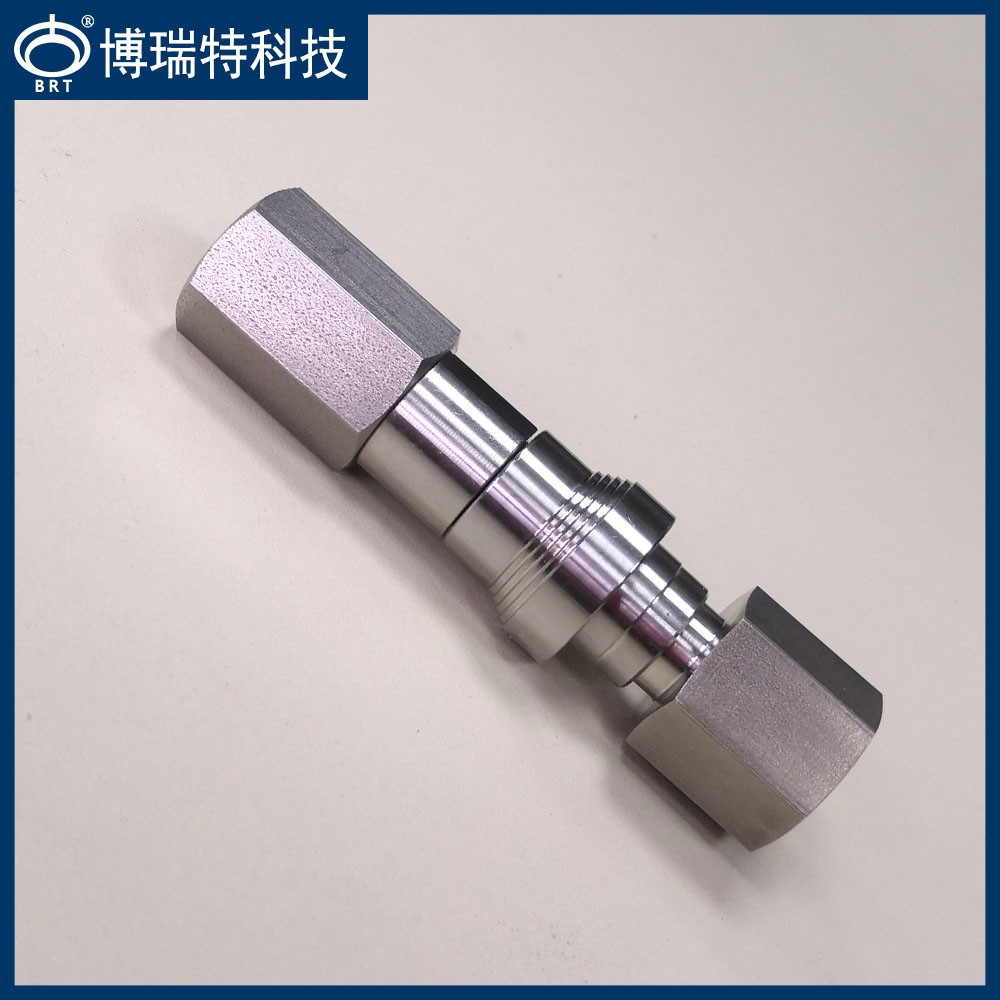

Bleeder Valve: The bleeder valve for purging the apparatus is a normal 1/4 in valve fitted into the side of the bleeder valve coupling. The lower end is threaded to fit into the end fitting of the upper chamber, and the upper end is threaded to receive the gauge coupling.

Lower Chambers: This chamber is a cylindrical vessel of such a volume that the ratio of the volume of the upper chamber to the volume of the lower chamber is between the limits. In one end of the lower chamber is provided to receive a suitable Staright-Through Valve. The other end of the chamber is equipped with a 1/4 in Inlet valve

Pressure Gauge: The range and gradustions of the pressure gauge used shall be governed by the bapor pressure of the sample being tested.

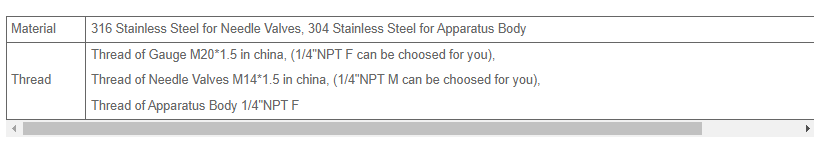

Inlet Valve: 316 Stainless Steel, Needle Valves, 3000psi

Note:

1. Samples shall be obtained and stored in accordance with Practice D1265 unless the test samples can be taken directly from the source of the material to be tested.

2. Assemble the apparatus with inlet valve of the lower chamber open, the straight-through valve between the two chambers open, the bleeder valve closed, and with the proper range pressure gauge attached.

Keywords:

ASTM D1267 Gauge Vapor Pressure of Liquefied Petroleum (LP) Gases Test Bomb, Gasoline and Diesel Typical Vapor Pressure Apparatus with Valves, Upper and Lower Chambers according to ASTM D323